Services

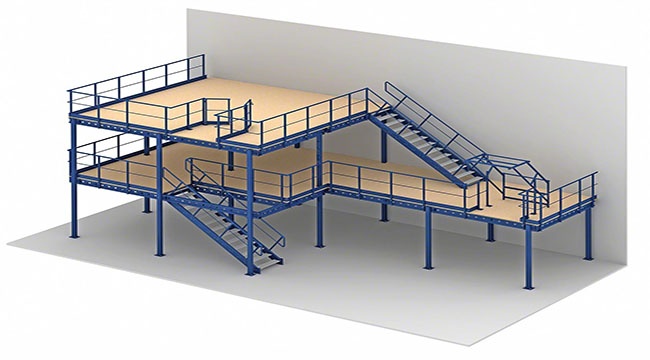

Fabrication Structural Steel & Plate Work (Medium & Heavy)

We fabricate structural steel work for various equipment supports, building services and other structures. Our expertise, workshop and experience in all types of Fabrication Worksare most enviable by our competitors. Machining & Mechanical Machining of different high precision spare parts and components based on the drawings or samples. E.g. Reduction Gears & Motors, Upper Traction Elevator Unit, etc. The company has many years of experienceproviding excellent service to various clients in the medium and heavy industry. Maintenance & Site InstallationPowder Coating

We would like to introduce ourselves as one of the efficient Powder coating vendors with an experience of 15 years in this field, We have got Enough spare capacity to cater to all the powder coating requirements. Here are some details of our plant We have a seven tank pre treatment facility for cleaning of the components of oil, rust and any other residual dirt and giving a good and fine base surface required for powder coating of the same. Our seven tanks are 8’.0”(L) x 4.0”(W) x 4 “(D)having a overhead electric hoist of 1 ton capacity with 2 HP motor for easy & fast movement of the components while pre treatmen.

Details of treatment process:

- Derusting & Degreasing ( 2 in 1)

- Water Rinse

- Activation

- Phosphating

- Passivation ( Zinc) each of the above process has got a specific time as per standard norms.

We also maintain a regular register daily to check the quality of the bath. Required additional process of chemicals are carried accordingly. After giving required times as per specification for pretreatement we have a demarked space for unloading of the treated material and drying of the same is done with the help of 30” industrial fan.

We have got powder coating booths, with powder coating guns,

The details of which are as under

4’ x 4’ x 3’ with powder coating machine of astorn.

2 powder coating guns of astron make mitsuba compatible.

Our powder coating area is with sufficient natural and artificial light Systems. We have got contract labour having 2 gunman and 5 helpers which can be increased as and when necessary. We have got 2 supervisors for each shift of 12 hours with 7 years’ Experience in pretreatement and powder coating field which are constantly Supervising the entire process and carrying out random inspection with the necessary tools and equipment’s required for the same, till the Material is ready for final dispatch. We usually maintain a standard thickness of 60 to 65 microns on the components. Any specific thickness requirements will be catered by us as per your specification.

We have got compressors of 5 HP capacity which are run on alternate days to control to avoid any break down problems.